Revving Up Your Knowledge: Drone Motor Replacement Insights

As drone technology evolves, so does the need for pilots and enthusiasts to understand the intricacies of maintaining these aerial marvels. Like any precision machinery, drone motors are subject to wear and tear, and knowing how to diagnose, repair, or even innovate with them is a crucial skill. The digital landscape is buzzing with shared knowledge, and several YouTube creators are offering valuable insights into drone motor replacement. This article, aligned with the spirit of "Drone Motor Makeovers: DIY Repairs & Innovations 🚀🛠", distills key takeaways from recent videos, providing you with a pilot’s-eye view on keeping your fleet flight-ready. We’ll explore practical repair techniques, innovative uses for drone motors, and essential maintenance tips to ensure your missions are always a success.

Key Takeaways from the Digital Hangar

Here’s a breakdown of the essential insights gleaned from our video analysis, focusing on practical applications and best practices for drone motor maintenance and replacement:

-

Troubleshooting is Paramount (Video 3): Before any replacement, a systematic approach to troubleshooting is critical. As highlighted in the "Drone Repair & Maintenance Guide," identifying the root cause of a motor issue – be it connectivity problems, sensor malfunctions, or actual motor damage – saves time and resources. Think of it like pre-flight checks; a thorough diagnosis prevents unnecessary component swaps.

-

DIY Repairs are Increasingly Accessible (Videos 1 & 6): The videos showcase the feasibility of DIY motor repairs, even for mini drones. We see examples of battery issues mimicking motor problems (Video 1), emphasizing the importance of checking all potential causes. The "how to repair mini Drone motor" video (Video 6) suggests that with careful hands and the right guidance, even intricate repairs are within reach for the dedicated enthusiast. Remember, safety first! Always disconnect power sources before attempting any repairs.

-

Understanding BLDC Motors is Key (Video 5): The video focusing on "drone motor BLDC" underscores the prevalence and importance of Brushless Direct Current (BLDC) motors in drone technology. Understanding their operation and potential failure points is crucial for effective maintenance and informed replacement decisions. BLDC motors offer efficiency and longevity, but their internal components can still require attention.

-

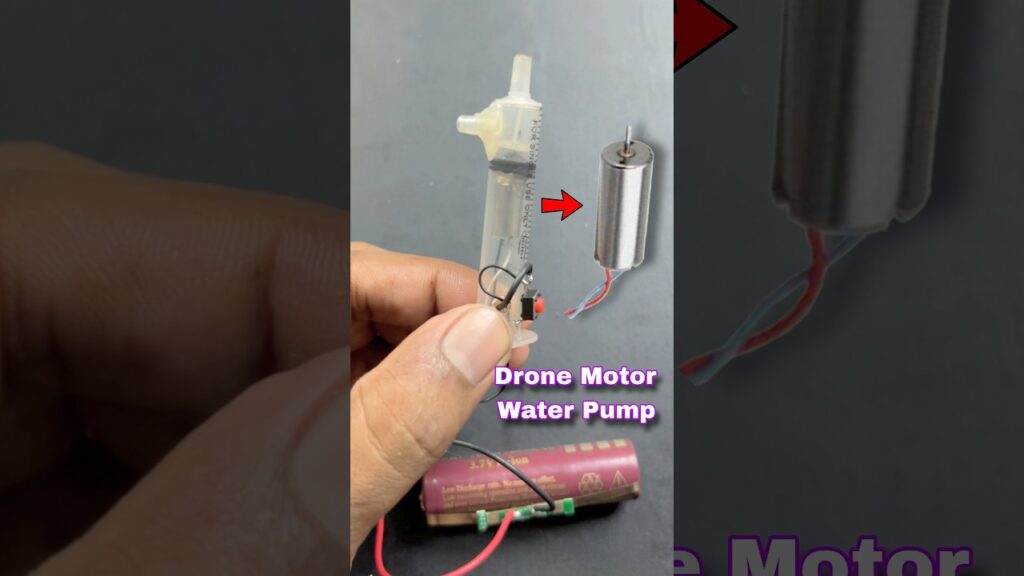

Drone Motors Have Versatile Applications (Videos 2 & 4): While our focus is replacement within drones, videos showcasing drone motors powering water pumps and generating electricity highlight their robust design and potential for repurposing. This speaks to the inherent quality of these motors and opens up avenues for creative innovation, even with "retired" drone components. Thinking beyond the drone frame can lead to unexpected applications.

-

Visual Guides are Invaluable: The very nature of YouTube videos provides visual step-by-step guidance, which is immensely beneficial for tasks like motor replacement. Seeing the process of removing old motors, connecting new ones, and ensuring proper wiring provides a clarity that text alone cannot achieve. Pay close attention to the techniques demonstrated, especially concerning delicate connectors and wiring.

-

Community Knowledge Sharing is Powerful: The comments sections and the very act of sharing these videos foster a community of learning. Pilots and enthusiasts can learn from each other’s successes and failures, accelerating the collective understanding of drone maintenance and repair. Don’t hesitate to engage with these communities; shared experience is a valuable resource.

Decoding the Data: Practical Application and Safety Considerations

While some videos showcase innovative uses for drone motors outside of their intended purpose, our primary focus remains on maintaining operational flight capabilities. The insights gained from these videos reinforce the importance of:

-

Regular Inspections: Just like pre-flight checks for your aircraft, regular visual inspections of your drone motors for any signs of damage, loose connections, or unusual wear can prevent in-flight failures. Listen for any unusual sounds emanating from the motors during operation; this can be an early indicator of a problem.

-

Proper Tooling: Having the right tools for the job is paramount. Delicate electronics require precision instruments. Using the correct screwdrivers, soldering equipment (if necessary), and wire strippers minimizes the risk of damaging components during replacement.

-

Understanding Motor Specifications: When replacing a motor, ensure the new motor matches the specifications of the original. Factors like KV rating (RPM per volt) and physical dimensions are critical for maintaining optimal flight performance and avoiding compatibility issues. Refer to your drone’s documentation for specific motor requirements.

-

Safe Handling of Components: Drone motors often contain strong magnets. Be mindful of this when handling them, keeping them away from sensitive electronics and ensuring they are stored safely to prevent accidental damage.

Ready to Dive Deeper?

The world of drone motor maintenance and repair is constantly evolving, driven by both necessity and innovation. The creators behind these YouTube videos offer valuable glimpses into practical techniques and creative applications. By understanding the core principles of troubleshooting, repair, and component knowledge, you can empower yourself to keep your drones in peak condition and explore the full potential of this technology. Scroll down to explore the video highlights and witness these "Drone Motor Makeovers" in action.