Soaring Above the Rails: How Drones are Revolutionizing Infrastructure Maintenance 🚀

For us drone enthusiasts, the sky isn’t the limit, it’s just the beginning! And when you start thinking about applying our amazing aerial tech to real-world challenges, the possibilities are truly exciting. Take railway infrastructure, for instance. Miles and miles of track, bridges, power lines – traditionally, inspecting all that has been a slow, often dangerous, and incredibly labor-intensive process. But now, imagine a nimble drone, equipped with high-resolution cameras and even LiDAR, zipping along the tracks, capturing every detail with pinpoint accuracy. That’s the reality we’re diving into today, exploring how drone-powered rail inspections are not just an upgrade, but a full-blown revolution in infrastructure maintenance. Several fascinating YouTube videos have recently surfaced, offering glimpses into this exciting field. Let’s unpack their key insights and see what the future holds for drones and railway upkeep.

Key Takeaways from the Drone’s-Eye View

Here’s what we’ve gleaned from the recent buzz around drone-based rail inspections:

- Comprehensive Data Capture is King: As showcased in the HiiLSEDrone + Hepta video, the combination of different sensor technologies on drones is a game-changer. They’re not just snapping pretty pictures. We’re talking about LiDAR creating georeferenced 3D point clouds for precise measurements, RGB cameras for detailed visual inspections (think spotting hairline fractures), and even infrared cameras to detect heat anomalies in power lines – potential indicators of serious issues. Imagine the detail! It’s like giving maintenance crews X-ray vision.

- Remote Control, Real Impact: The collaboration between Frequentis and the Austrian Railway Company (BB), highlighted by Roman Stickler, is fascinating. The idea of strategically placed drone hangars allowing controllers in Vienna to launch inspections hundreds of kilometers away is a testament to the power of UTM (Unmanned Traffic Management) systems. This signifies a move towards greater automation and efficiency, reducing the need for boots on the ground in potentially hazardous areas.

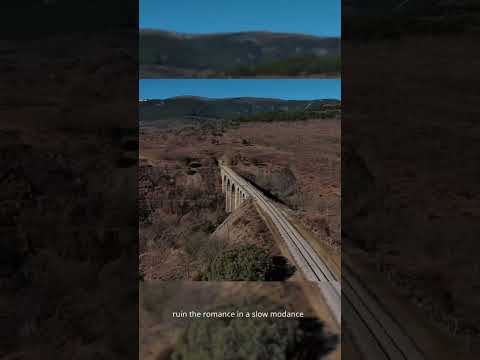

- Safety First, Efficiency Always: The Drones #railway #innovation #engineering video succinctly emphasizes the core benefit: replacing risky manual inspections. Think about it – no more dangling precariously from bridges or walking along live tracks. Drones can access those tricky spots – roofs, bridges, coastal areas – with ease and safety, sending back high-quality data for analysis. This not only protects personnel but also speeds up the inspection process considerably.

- Focus on Critical Components: The S&C inspection with drones video focuses on a particularly crucial aspect of railway infrastructure: switches and crossings. These are complex mechanical systems prone to wear and tear. The video highlights how drones, coupled with photogrammetry software, can autonomously inspect these components. This level of detailed, automated inspection is vital for preventing disruptions and ensuring smooth rail operations.

- Versatility Across Applications: Even drone manufacturers like Autel, as seen in their video, are showcasing the adaptability of their commercial drones for railway line and bridge construction inspections. This underscores the broad applicability of drone technology in the rail sector, from routine maintenance to monitoring new construction projects.

The Bigger Picture: Automation, AI, and the Future of Rail Maintenance

What’s truly exciting is how these individual applications are starting to paint a picture of a more interconnected and intelligent future for rail maintenance. We’re seeing the convergence of drone technology with sophisticated data analysis tools. Imagine the possibilities when AI algorithms are trained to automatically identify defects in the data collected by these aerial inspectors. This means faster detection, quicker response times, and ultimately, a safer and more reliable railway network.

Think about the workflows: a drone autonomously flies a pre-programmed route, capturing high-resolution imagery and LiDAR data. That data is then processed, perhaps even onboard the drone itself, using edge computing. AI algorithms analyze the data, pinpointing potential issues like cracked rails, loose fasteners, or vegetation encroachment. Maintenance crews then receive precise, actionable reports, complete with GPS coordinates and visual evidence, allowing them to address problems efficiently and effectively. This isn’t science fiction; it’s the direction we’re heading, and it’s thrilling to witness.

For us hobbyists, this also sparks ideas. What kind of custom payloads could be developed for even more specialized rail inspections? Could we integrate hyperspectral imaging to assess the health of ballast? Could swarm technology be used to inspect entire sections of track simultaneously? The possibilities are as vast as the rail network itself!

Eyes in the Sky, Efficiency on the Ground

The videos we’ve highlighted offer a compelling snapshot of how drones are rapidly becoming indispensable tools for railway infrastructure maintenance. From detailed visual inspections to advanced 3D mapping and thermal analysis, these aerial platforms are providing unprecedented levels of data and insights, leading to safer, more efficient, and ultimately, more reliable rail networks. It’s not just about replacing manual labor; it’s about augmenting human capabilities with the precision and reach of drone technology.

Ready to see these drone innovations in action? Scroll down to watch the video highlights and witness the revolution firsthand!